Before moving forward with the next steps in your robot programming, it’s essential to double-check that all previously defined settings—such as the robot, Tool TCP, and reference frame—are correct. This ensures accurate and repeatable operations. In the following video, you’ll see how to verify these settings using RoboDK. After the video, a detailed description will guide you through the verification process.

Align the Robot and Tool #

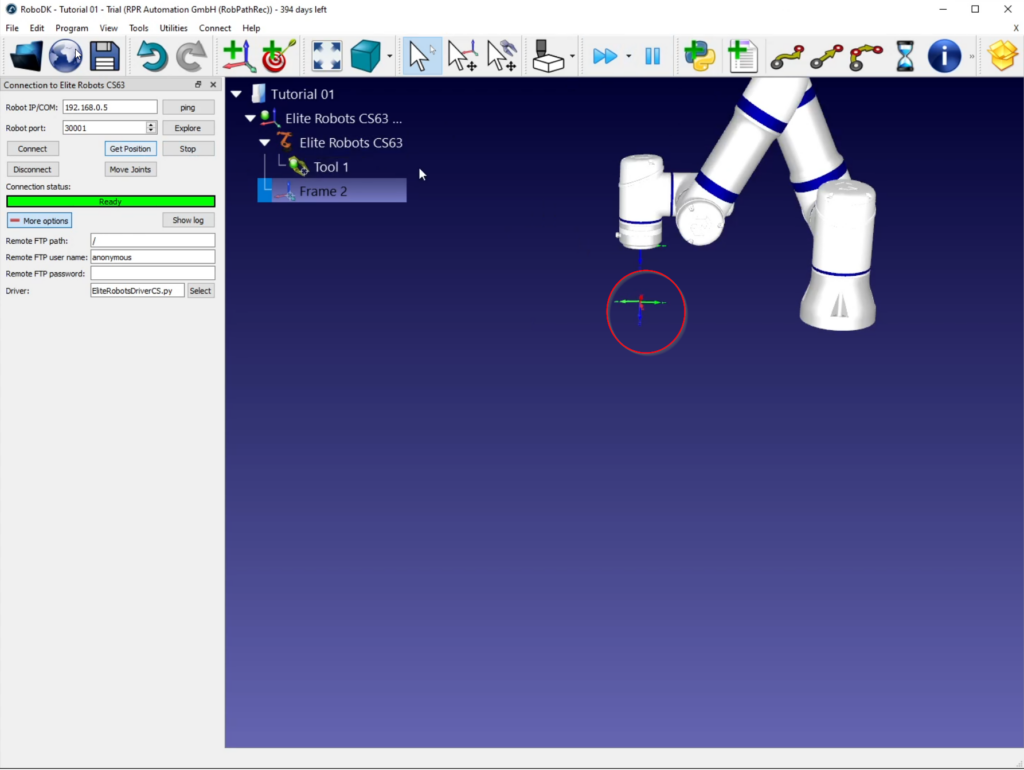

Start by positioning the robot at the zero point (Origin), where the tool is aligned with the workspace (e.g., the wooden plate).

Use free ride mode to adjust the tool’s position until it is near the zero point. You can refine the alignment with the jog mode.

Check the Robot’s Current Position #

After aligning the tool, use the Get Position function in RoboDK to check the robot’s position.

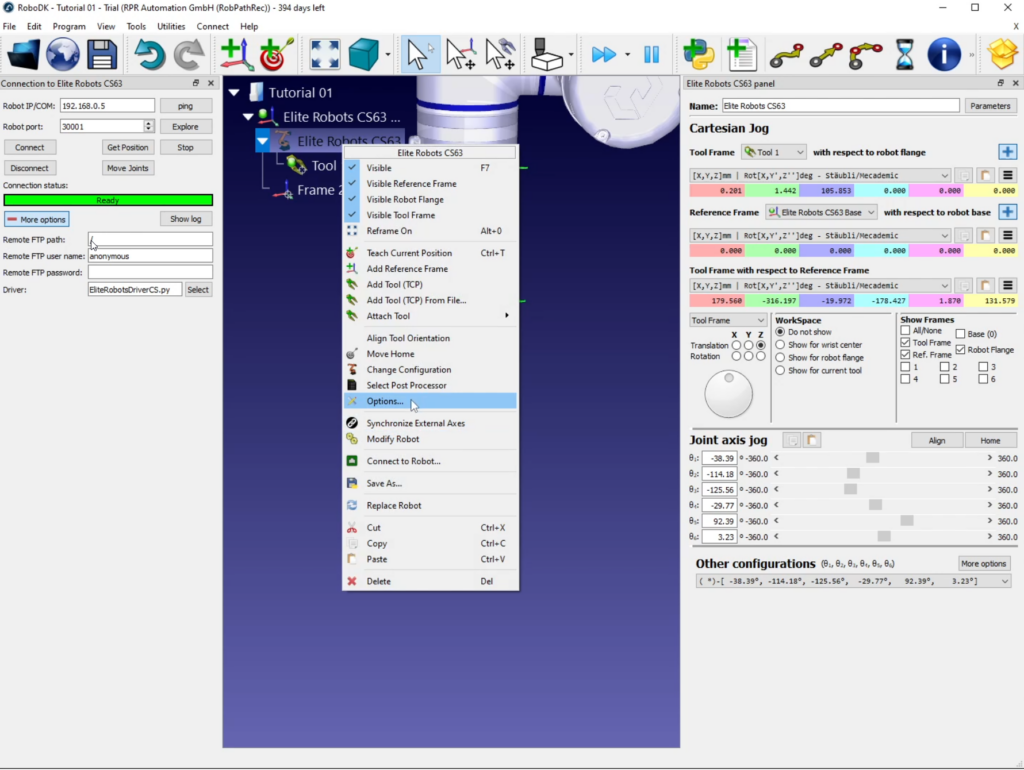

Open the robot’s properties window by pressing F3 or navigating to Options. This will display the tool frame values relative to the reference frame.

Inspect Tool Frame Values #

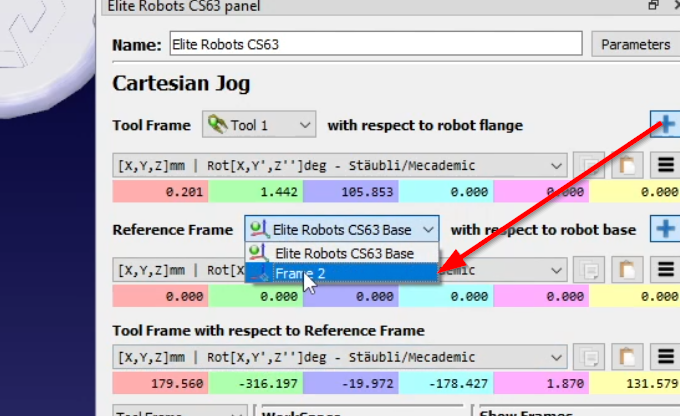

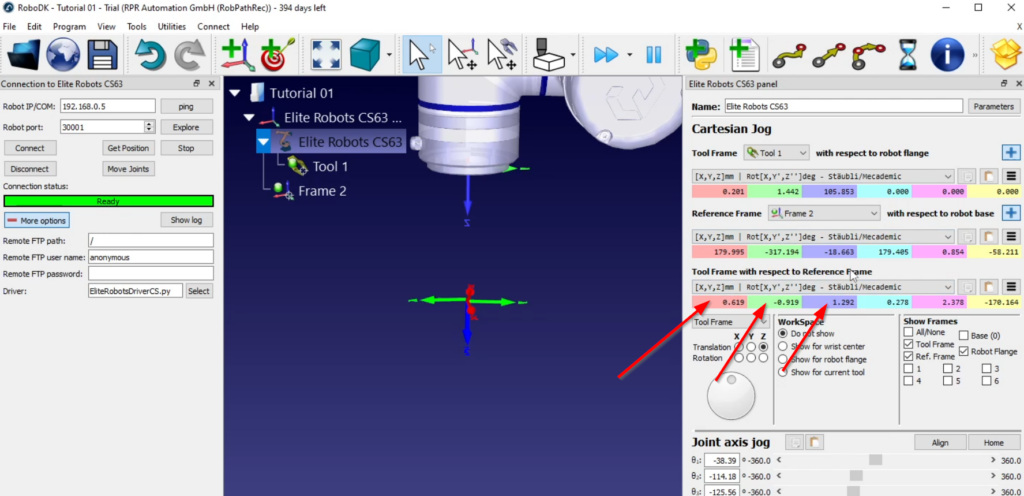

Look at the values for the tool frame, which represent the position of the tool tip (e.g., a pen) relative to the reference frame (e.g., the wooden plate).

In this particular case, we control the Origin position. So if the set-up were perfect, we should see 0, 0, 0.

The values 0.619, -0.919 and 1.292 are not too precise. Depending on the application, it can be critical.

Keep in mind: These deviations from 0,0,0 are the sum of the imprecise tool calibration, frame calibration and control positioning. If you want to reach better accuracy:

Verify the X, Y, and Z Coordinates #

Check the updated X, Y, and Z coordinates in RoboDK. For example, the X value should be close to 300.1004, which indicates a very precise result.

Continue to adjust the tool and verify each position until the values meet your expected tolerances.

Don’t OVERDO! #

In an ideal scenario, the tool’s Z value should be exactly zero when aligned with the reference frame, but slight deviations are acceptable for most tasks.

As long as the values are close to expected tolerances (e.g., a deviation of a few tenths of a millimeter, or even a millimeter), the settings are considered accurate for the task at hand. This is always depending on the application!

Once the robot’s position, Tool TCP, and reference frame have been verified, save your updated settings.

These settings ensure that the robot’s operations will be consistent and precise moving forward.